Featured

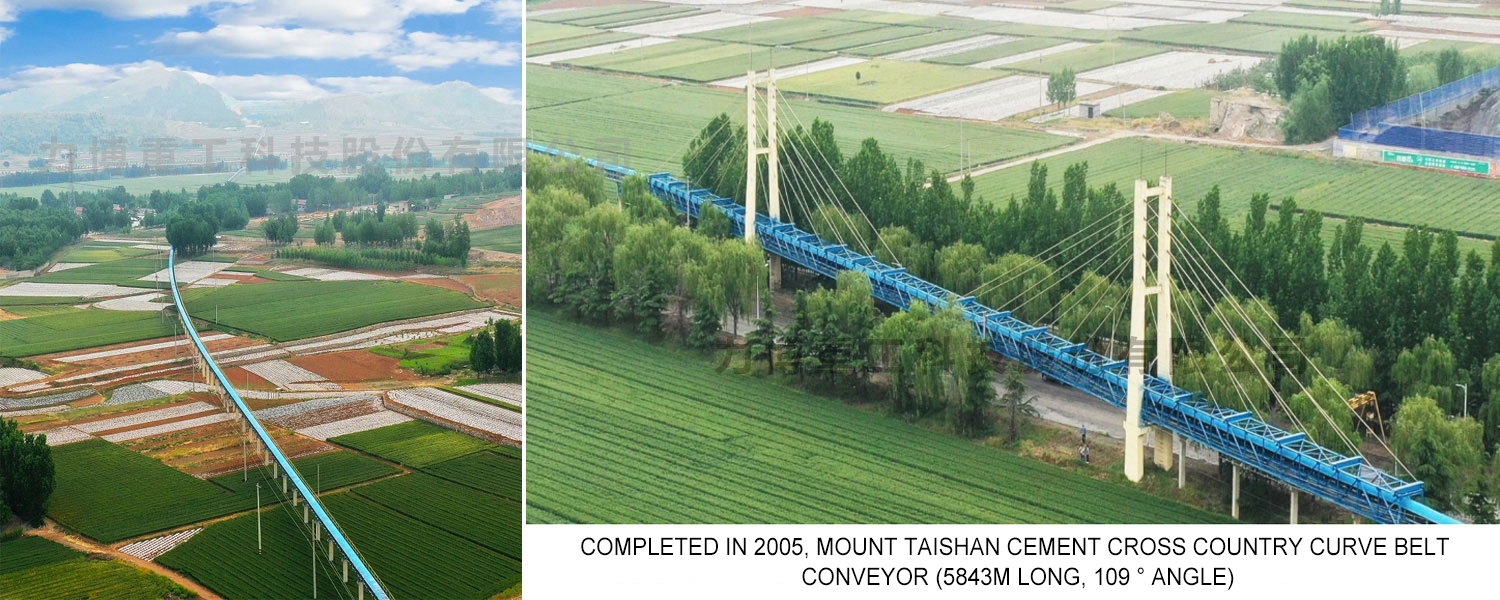

◆ Long distance and large capacity space turning belt conveyor (the first example was put into operation in 2005, with 19 achievements, and won the second prize of the National Science and Technology Progress Award in 2019)

◆ Large angle upward belt conveyor (maximum inclination+38 °)

◆ Large angle downward conveyor and power generation technology (maximum inclination angle -35 °, maximum single machine power 4 x -1000 kW)

◆ Bidirectional feeding technology (saving land and investment)

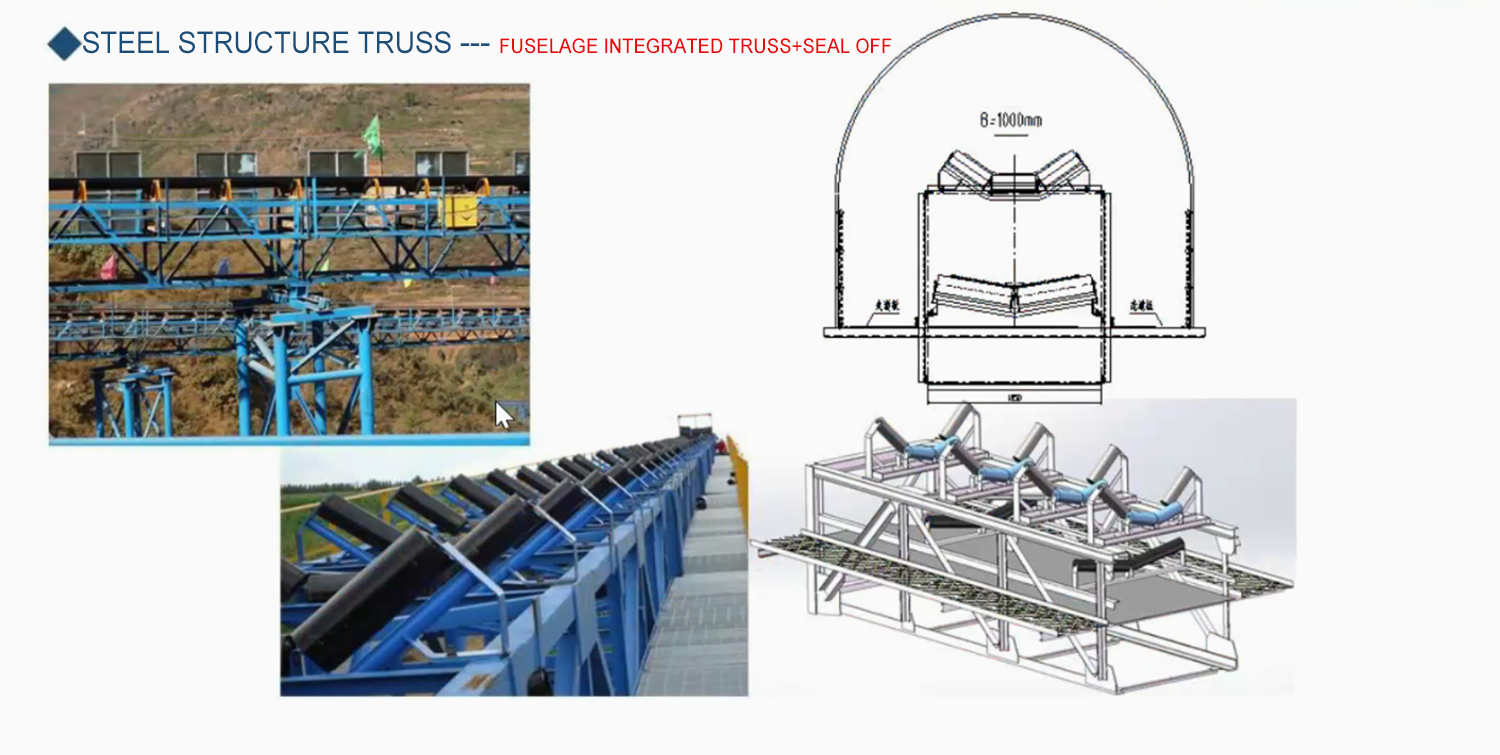

◆ "Integrated" design technology of belt conveyor and steel structure truss (saving investment)

◆ Using suspension bridges or cable-stayed bridge structures to achieve large span technology (reducing construction lifting difficulty and saving investment)

◆ Linear friction drive (braking) device (reduced belt strength selection specification)

◆ Intelligent permanent magnet direct drive conveyor system (improves transmission efficiency, efficient and energy-saving. Abandons reducers and reduces fault points)

◆ Open pit displacement belt conveyor

◆ Machine head walking (retractable) belt conveyor

◆ Controllable torque limiting safety braking device (specifically designed for safety braking of large angle upward conveyor belt)

◆ Turning adaptive adjustment roller group

Intelligent control technology (invented adaptive control technology for multi-point drive belt conveyor systems, solving problems such as power balance among multiple machines in belt conveyor systems)

◆ Safety protection technology (invention of controllable safety braking, torque limiting backstop, and belt breaking catcher)

In order to save total investment, reduce construction difficulty, and reduce steel consumption, LIBO Company widely adopts belt conveyor and steel truss integrated structure

To solve the problem of lifting large-span trusses, LIBO Company adopts unique cable-stayed bridge design technology and integrates belt conveyor and truss design, effectively solving the problems of crossing valleys, rivers, highways, railways, and other areas, and has won high praise from users.

The production line independently developed by LIBO Company ( is similar to automotive paint baking)

Principle

Electroplating: It is the process of coating a thin layer of metal on a metal (or non-metallic) surface

Electrophoresis: It involves coating a metal surface with a resin like coating to prevent surface oxidation and beautify the surface

Characteristic

Electroplating: Has a metallic texture and generally cannot penetrate into concealed areas

Electrophoresis: High imitation electroplating, coating can fully cover concealed areas, such as inner walls and depressions

Durability comparison

Paint: if the surface treatment is not thorough for 1 year, rust will return

Electroplating:With high costs.Electroplating waste has a significant impact on nature and is gradually phased out

Electrophoresis: Similar to car baking paint