Intelligent Control Technology

Intelligent control system

The common short distance belt conveyor has a short head to tail Centre-to-centre distance (within two or three hundred meters). It is equipped with a single drive device, one button start and stop, and simple control. Long distance (within 20 kilometers) space turning belt conveyors involve complex working conditions such as dispersed driving at the head and tail, multi-point braking, large undulations along the belt and space turning, and large angle up and down transportation. Rubber-belt is a special material of viscoelastic material, and these comprehensive factors put forward very strict requirements for the adaptability of the conveyor control system.

Based on years of accumulated experience, our company has developed a complete intelligent control system that can effectively solve:

1. Multi drive power balance, smooth starting, and safe braking;

2. Effectively avoiding straps, stacking, and slipping;

3. Adaptive conveyor tension changes at any time;

4. Quickly locate fault points along the line;

5. Capable of remote operation and maintenance.

In short, LIBO Company's exquisite mechanical design and core components of the belt conveyor are all self-produced, coupled with an intelligent control system, which can ensure the safe, efficient, energy-saving, and environmentally friendly operation of the belt conveyor, greatly improving the reliability of the entire conveyor machine and reducing maintenance costs.

Intelligent Control Technology

⒈Adaptive Control Technology for Multipoint Drive (Braking) Belt Conveyor System

2. Bus type Address geocoding integrated protection system (or optical fiber passive integrated protection system)

3. Remote IoT operation and maintenance system

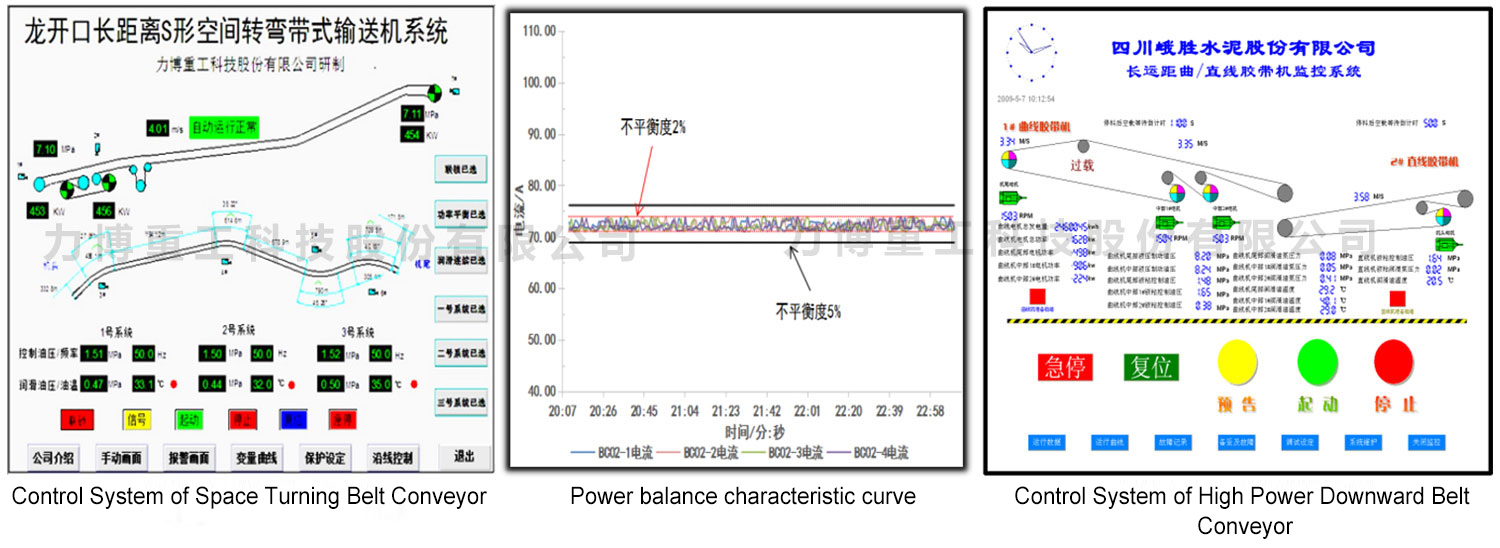

Adaptive control technology for multi-point drive (braking) belt conveyor system

The adaptive control technology of multi-point drive (braking) belt conveyor system effectively solves the problem of "large dynamic impact" caused by the viscoelastic body of the conveyor belt, making the control technology of China’s belt conveyor reach international leading level.

Application case of adaptive control technology for multi-point drive (braking) belt conveyor system

2.1 Bus type Address geocoding integrated protection system

The Address geocoding integrated protection system has solved the problems of long distance belt conveyor, such as difficulty in fault location, susceptibility to electromagnetic interference, and inconvenient wiring, making the control system simpler, more reliable, cheaper, and easier to maintain.

Functional features:

◆High speed communication, easy scalability

◆Extremely reliable data transmission

◆Multiple input points, allowing for simultaneous access to multiple sensors

◆ Non polarity wiring

◆ Any topology

Excellent anti-interference ability

◆ Powerful comprehensive protection host expansion function

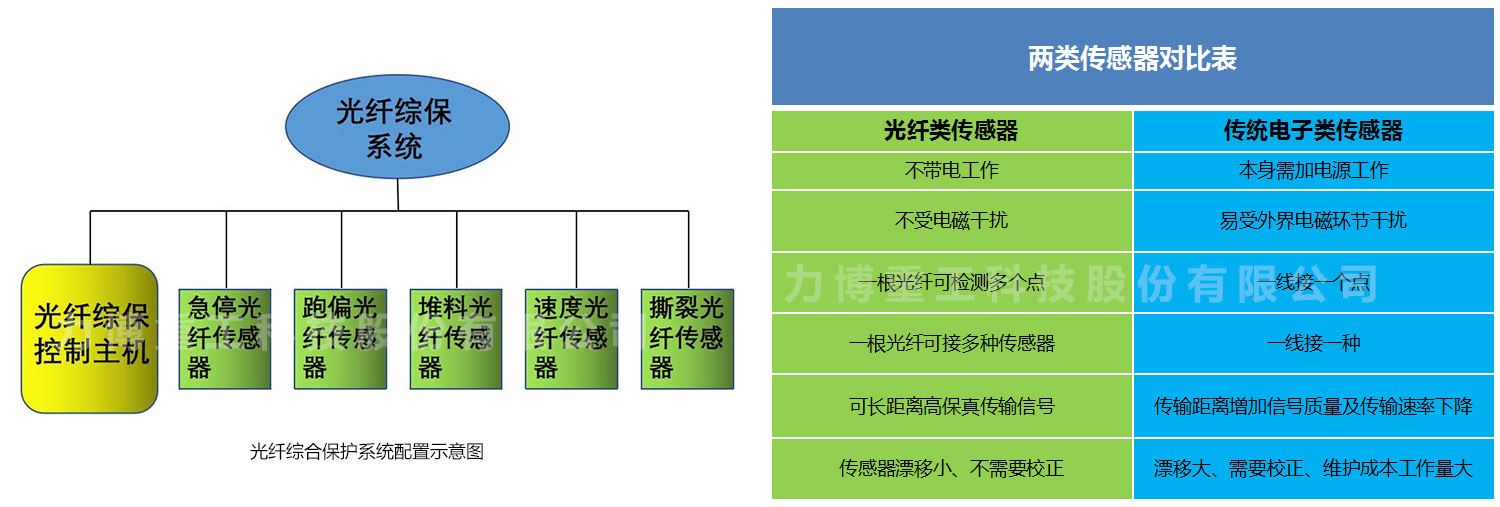

2.2 Fiber optic passive comprehensive protection system

The fiber optic passive comprehensive protection system abandons traditional electronic sensors and innovates the use of fiber optic passive sensor components. A real-time monitoring system for the comprehensive protection status of belt conveyors based on fiber optic detection has been developed, completely solving the problems of kilometer level belt conveyor control systems such as difficulty in locating faults due to distance, high voltage drop along the line, and serious communication interference.

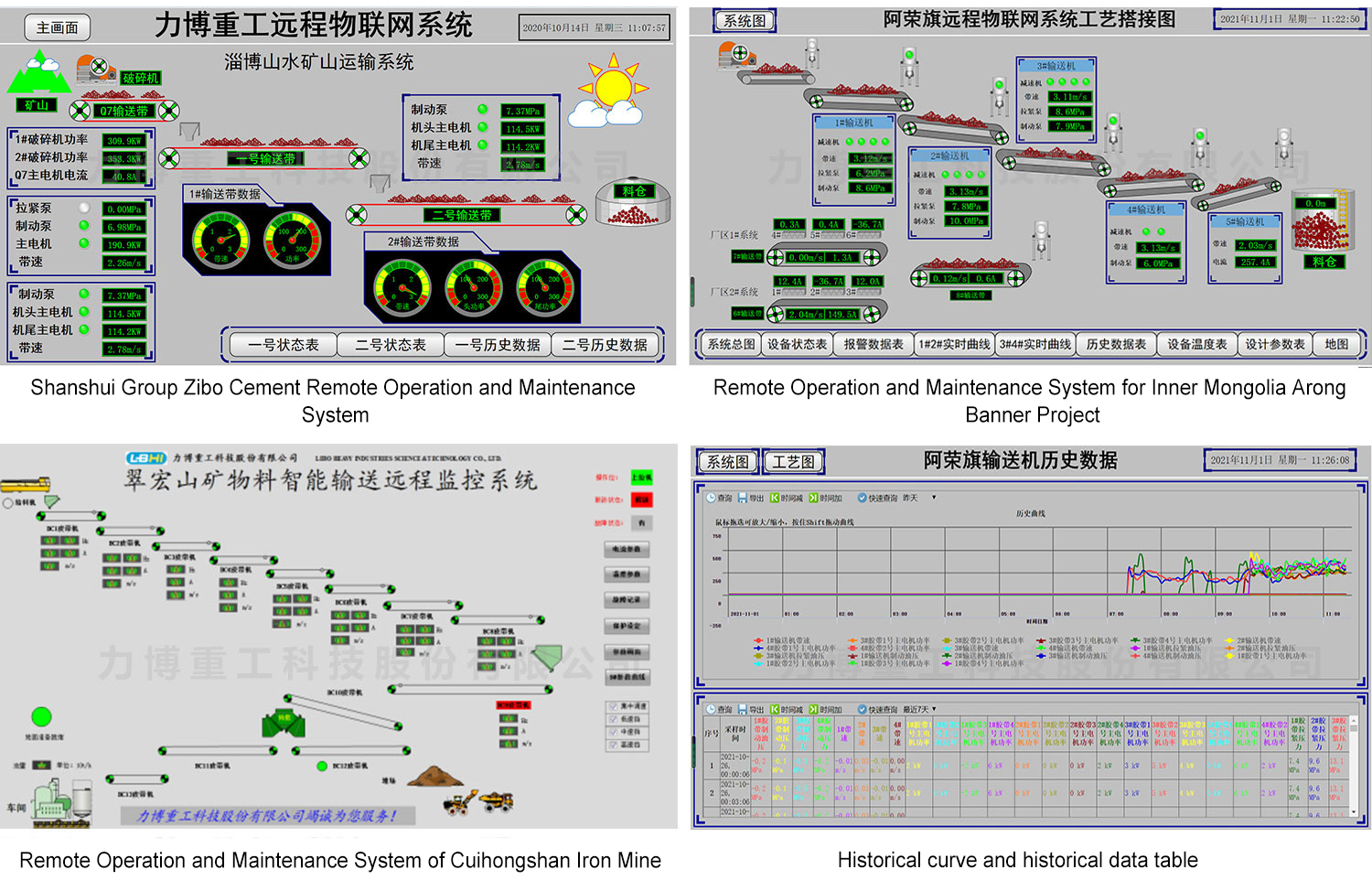

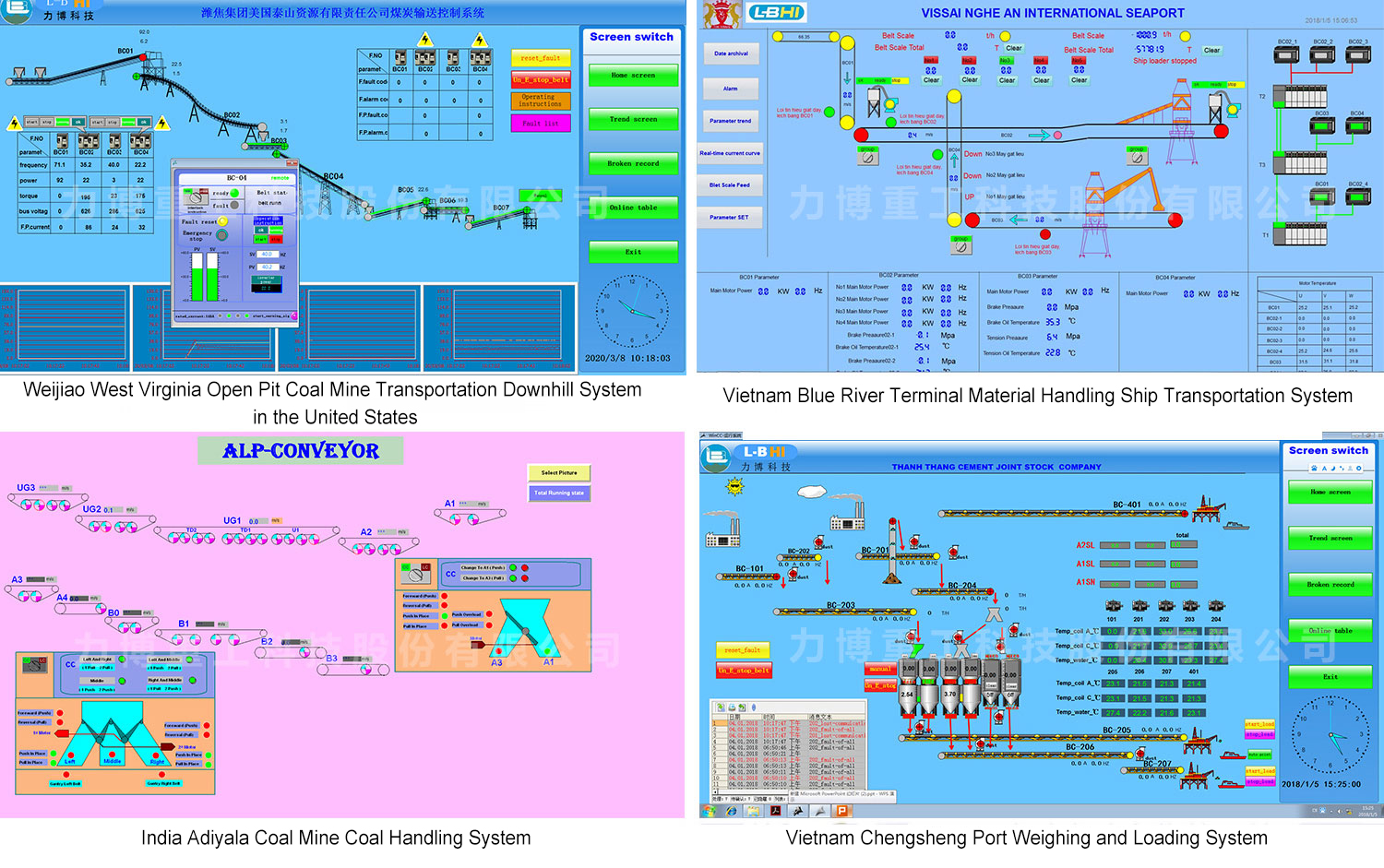

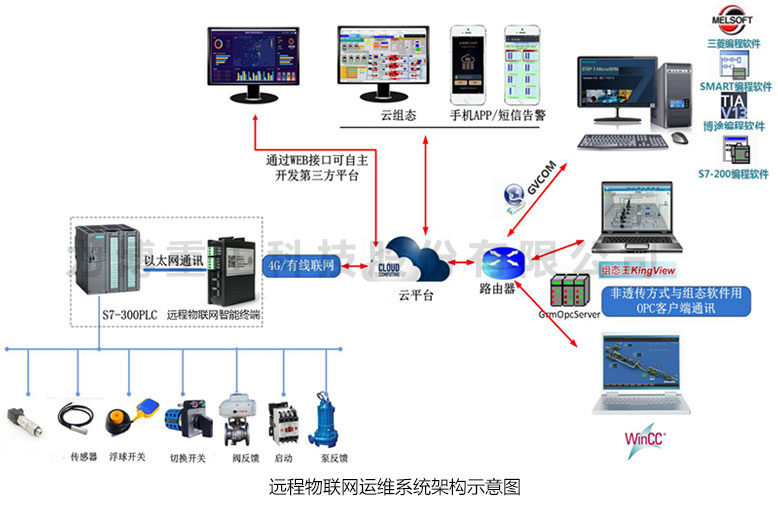

3. Remote IoT operation and maintenance system

The remote IoT operation and maintenance system can achieve functions such as "remote upload and download of programs, mobile app and webpage monitoring, cloud configuration, remote operation and maintenance configuration data recording, program optimization, alarm WeChat push, and remote online assistance in troubleshooting". The device's operating status is clear at a glance and within reach; Equipment maintenance is simpler and faster.

Functional characteristics:

◆ Remote computers do not require a fixed IP address, and can be achieved using a mobile phone (with internet access)

◆ Remote computer configuration software monitoring

◆ PC based universal webpage monitoring data

◆ IOS, Android mobile universal app monitoring

◆ Remote download and debugging of PLC ladder diagram, touch screen interface

◆ Support SMS alarm, dial reminder, and WeChat alarm

WEBGUI web page configuration software

◆ Provide standard Webservice secondary development interfaces

◆ Historical data, alarm SMS Cloud storage service

Application Cases of Remote IoT Operation and Maintenance System